7 Simple Techniques For Casters Manufacturer

Wiki Article

Facts About Casters Manufacturer Uncovered

Table of ContentsThe Single Strategy To Use For Casters ManufacturerWhat Does Casters Manufacturer Do?Little Known Facts About Casters Manufacturer.8 Easy Facts About Casters Manufacturer ExplainedSome Of Casters ManufacturerThe smart Trick of Casters Manufacturer That Nobody is Talking About

While a lot of synthetic wheels are ideal for high-impact and severe scenarios, they are louder than softer materials and are much less forgiving when ramming particles. Phenolic wheels, which are made of phenolic resin and macerated canvas, are a regular option for push pull applications. Phenolic wheels are strong and stand up to oil and also other chemicals, making flexibility simpler.Gray iron is made use of to make cast iron wheels. Some of the specs found on this caster wheel include firmness of 90-95A; Brinell 145.

This kind of caster wheel can run in the following conditions: light chemicals, oily and greasy locations, steel chips externally, high heat (+250 F), and also extreme cold (+45 F). To minimize directing as well as rolling effort, the flanged wheel is developed to run on steel tracking. Moving on tracks has actually the added advantage of lowering the toll of load capacities on floorings, permitting bigger capacity, simpler rolling, and also flooring protection.

7 Easy Facts About Casters Manufacturer Shown

The solid wheels are solid in typical usage, can endure heats, and also soak up shock and effect without failure. Created steel wheels outshine ductile steel wheels in terms of load capacity, impact strength, and rollability of all wheel wheels. Built steel wheel wheels can be run on concrete and smooth steel surface areas.

Bearings that can be used consist of plain, tapered, Teflon, as well as roller bearings. These caster wheels can operate under the same problems which are moderate chemicals, oily as well as greasy locations, and metal chips externally. These wheels are made up of a nylon as well as glass mix and also are engineered to endure extreme temperatures.

See This Report on Casters Manufacturer

Glass loaded nylon caster wheels have a firmness of 65D. These caster wheels use either plain, roller, or spanner bearings. Glass loaded nylon wheels can also operate within the temperature level variety of approximately 490F continuous or 550F periodic. These caster wheels are likewise ideal to be operated the adhering to floor kinds: carpet, block as well as concrete, linoleum, asphalt, terrazzo as well as wood, smooth steel, and tiled floorings.Formed unscathed, black or grey is the most usual shade. Tough rubber wheels have a bigger load capability than soft rubber wheels as well as will not flatten while sitting under loads, unlike soft rubber wheels. They have good rolling ability, are easy to start, and are resilient. Most chemicals, oils, grease, solvents, and also cleansing representatives are immune to tough rubber wheels (Casters Manufacturer).

How Casters Manufacturer can Save You Time, Stress, and Money.

Tough rubber wheel wheels bring about noise reduction and floor defense. Rubber wheels with air inside that give optimum flooring defense as well as the capability to roll over diverse challenges. Pneumatically-driven wheels supply cushioning as well as anxiety absorption, making it appropriate for transporting sensitive lots over a variety of flooring surfaces. Pneumatically-driven caster wheels are well matched for aerospace as well as other applications.They secure the flooring, are non-marking and also non-conductive, and withstand abrasion better than tough rubber wheels. These wheels are immune to water, oils, oil, solvents, and many chemicals, making it perfect for application in bakeries, dairy, food mill, meat important source processing, washings, grocery stores, storehouses, and also production. The additional thick, completely shaped grey rubber step is chemically adhered to a light weight aluminum core for amazing toughness and also activity on these wheels.

Not known Facts About Casters Manufacturer

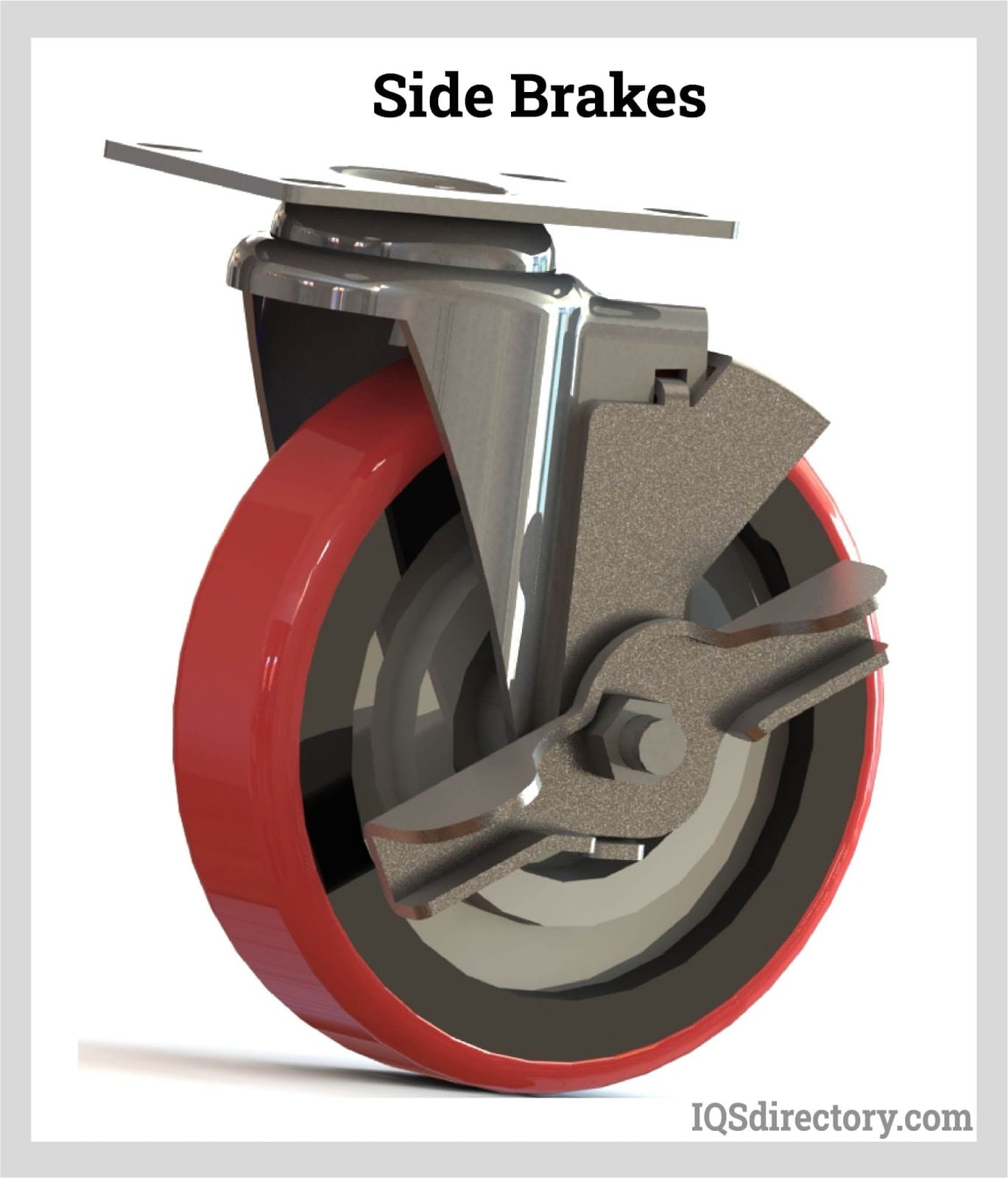

The "V" groove's style makes certain optimum weight distribution per wheel. For sturdy industrial casters with brakes, brakes are a prominent alternative. Brakes allow users to stop and maintain carts in position, which can be valuable in some situations or increase safety by lessening the threat of a runaway cart. There are numerous selections of wheel brakes readily available, each with its own set of characteristics.A polyurethane camera is used in the polyurethane cam wheel brakes. The camera is after that made use of to secure the wheel ready by tightening up a plate versus the wheel's running surface. A variety of devices, including deals with and also levers formed directly right into the cam, can be utilized imp source to operate the cam.

One more benefit of this kind of brake is that the actuation approach can be finished with the feet, which removes operator pressure from bending down to activate with a hand - Casters Manufacturer. These brakes can be set up on a wheel's leading or trailing edge. Face get in touch with brakes function by pressing a plate onto the wheel's running surface making use of a threaded rod.

The Only Guide to Casters Manufacturer

These brakes provide a strong holding pressure and also appropriate for durable applications. These brakes can be mounted on a caster's leading or trailing edge. The disadvantage of this form of brake is that it calls for the driver to bend over and tighten or loosen up the brake by hand, which puts a lot more pressure on the operator and takes longer than a foot actuated brake.Report this wiki page